Featured Posts

8 Reasons Why Many Patients Prefer Dental Implants

The implant can restore your smile to its good health and strength. From being comfortable to making one feel confident, some positive aspects of these implants can make a big difference in how you laugh or think about yourself. This is why most patients would […]

health

What is a Personal Injury Demand Letter?

In Personal injury, you can come across a special demand letter. It is similar to a letter you write when you have been injured or need assistance. Here is all about demand letters and why they are crucial, particularly when someone has been hurt in […]

Law & Legal

6 Ways Meditation Helps Improve Physiotherapy Outcomes

Have you ever heard of a situation where meditation has benefited people who are sick and need a quick recovery? MVA physiotherapist also confirms that meditation may be used to attain pain reduction and reduce anxiety levels. Moreover, it has additional benefits in bringing one’s […]

health

8 Reasons Why Many Patients Prefer Dental Implants

The implant can restore your smile to its good health and strength. From being comfortable to making one feel confident, some positive aspects of these implants can make a big difference in how you laugh or think about yourself. This is why most patients would […]

healthThe implant can restore your smile to its good health and strength. From being comfortable to making one feel confident, some positive aspects of these implants can make a big difference in how you laugh or think about yourself. This is why most patients would go for dental implants instead of other procedures.

1. They Look and Feel Natural

When you have a missing tooth, an implant usually looks so natural that no one will know. Eating or speaking feels like it is your teeth. So, you can always smile and chew without worrying about being unfamiliar or different. This, therefore, means that with the help of implants, you can get a natural smiling face.

2. Sturdy and Long-lasting

These dental implants could last for several years. This makes them ideal for people with sensitive teeth or wanting long-term tooth replacement. This means they dot need to be frequently replaced by anyone using them, giving them more time to enjoy their smiles without worrying about their teeth health.

3. Better Oral Health

Good oral health requires maintaining strong, healthy teeth and gums, so dental services involve replacing missing teeth and ensuring that jawbones remain firm through dentures. Dental implants prevent the shrinking or weakening of the jawbone after losing its tooth. But when left unattended, it shrinks because the tooth is gone, resulting in loss of bone from the jaw structure.

4. Improved Comfort

Occasionally, dentures may not fit perfectly, especially if they rub against your gum, causing discomfort. However, unlike them, dental implants are like mouth’s custom-made shoes. They fit correctly, and no pain or irritation is experienced while eating, talking, and laughing. With Implants, you can speak, eat, and smile without discomfort due to denture-related problems.

5. Ease of Use and Functionality

With dental implants, you can enjoy all your preferred meals. You can talk to your friends and brush your teeth as usual. They fit so well and work so smoothly that you will not remember even having them on. This means that you can eat without extra effort, have excellent talks, and keep your teeth clean; all these are natural processes. With dental implantation, everything comes naturally.

6. Stability and Assurance

Once they are in place, they offer the wearer a firm fit that does not come loose or move around, providing stability. Therefore, eating or talking will be done without fear of losing one’s tooth.

7. Preserves Teeth Adjacent To The Missing One

Some treatments for replacing lost teeth may require modifying or removing the nearby ones to accommodate the new implant. There is no need to change any other tooth because an implant fits perfectly well within the gap left after extraction. This preserves their original looks and helps maintain a smile appearance. So even if the implant is still in place, other existing teeth remain unaffected.

8. Confidence Boosting

This new tooth fits seamlessly into your mouth and restores the original look of your smile. When you feel like your teeth look great, it rebuilds your self-esteem naturally. Therefore, this elevated confidence level makes one’s smile radiant and brightens their day.

Conclusion

Most patients highly favour dental implants since they come with many advantages that range from looking good and feeling right to lasting longer than other alternatives. They provide comfort, stability, and better oral health. They also restore self-image by boosting confidence by giving back a complete smile. For consultation and expert advice on dental implants, please contact us.

What is a Personal Injury Demand Letter?

In Personal injury, you can come across a special demand letter. It is similar to a letter you write when you have been injured or need assistance. Here is all about demand letters and why they are crucial, particularly when someone has been hurt in […]

Law & LegalIn Personal injury, you can come across a special demand letter. It is similar to a letter you write when you have been injured or need assistance. Here is all about demand letters and why they are crucial, particularly when someone has been hurt in an accident.

Definition of a Personal Injury Demand Letter

A demand letter about personal injury contains information on how one was injured, what happened and the amount requested as compensation.

Purpose of a Demand Letter

Demand letters aim to ask for money from those who caused injuries. These letters are meant to show why they owe the payment for damages. The sums such victims require are also included in this kind of correspondence, as they should be able to cover medical and other related expenses.

Components of a Personal Injury Demand Letter

Introduction

The introduction part of personal injury cases serves as an identifier. In addition, it informs the reader about your intentions behind writing the letter.

Statement Of Facts

In your demand letters statement of facts section, you can explain all events leading up to the accident or incident that caused your injury. You may also supply proof or prove negligence in slip and fall accidents or any other incidents precipitated by those addressed here.

Liability And Damages

Liability refers to who caused the harm, while damages refer to what bad things happened because the injury was caused. Hence, this part explains why the party you are writing to is accountable for your injuries and how these injuries have affected you.

Medical Treatment And Expenses

In this section, you should discuss the care you need due to this injury. You will also mention the doctors who treated it and the money you had to pay for medical bills.

Lost Wages

Lost wages are the earnings that a person fails because they cannot go to work due to their injury. This part explains how much income loss resulted from your injuries and why someone should make payment for this particular form of compensation.

Pain And Suffering

These terms refer to physical and emotional pain caused by your injury. In this paragraph, you describe the suffering, pain and other difficulties which have been brought about by your accident.

Demand for Damages

This is the part that shows how much money you want. It should be enough to cover your hospital bills, any lost chances of doing business, pain, and other things that have resulted from the accident.

Deadline for Response

The deadline for response is the day by which you expect the person you are writing to act as stated in the demand letter and reply to the sender of this request. It allows them some time within which they must answer and signifies your seriousness in pursuing compensation for injuries suffered during an accident.

Critical Issues To Consider When Writing A Demand Letter

Clarity And Brevity

Avoid using convoluted terms and phrases when drafting a demand letter since they make it hard for a reader to know precisely what you need and why. Keep your letter short but concise so that people can understand what you mean.

Documentation and Evidence

This must be considered; evidence supporting your claims is crucial when writing a demand letter. These may include but are not limited to medical records, receipts, and pictures of injuries sustained. Soundproof can boost one’s claim, thus making one’s demands more persuasive.

Professional Tone

This type of communication means always being respectful in one’s written appeal. The language shall be brief so that the script will use restrained vocabulary.

Specificity in Damages

Describe what expenses you have incurred due to the harm done to your body in exact terms like hospital bills and loss of work. Thereby making both sides aware of each other’s needs when communicating.

Legal Basis for Claim

When writing a demand letter, you must know why you are entitled to compensation in law. Therefore, you will have to prove that the individual you are addressing is liable for your injuries and should be made to pay you.

Conclusion

Demand letters can greatly help after any accident. Please keep it simple and friendly and list the specifics when drafting one of these letters. It may look like narrating your story and requesting assistance politely. Feel free to ask to a Injury lawsuit attorney about writing a demand letter or more on how personal injury cases can be handled easily.

6 Ways Meditation Helps Improve Physiotherapy Outcomes

Have you ever heard of a situation where meditation has benefited people who are sick and need a quick recovery? MVA physiotherapist also confirms that meditation may be used to attain pain reduction and reduce anxiety levels. Moreover, it has additional benefits in bringing one’s […]

healthHave you ever heard of a situation where meditation has benefited people who are sick and need a quick recovery? MVA physiotherapist also confirms that meditation may be used to attain pain reduction and reduce anxiety levels. Moreover, it has additional benefits in bringing one’s mind and body together more effectively. Here is the role of meditation in our health and recovery.

- Reduction of Stress and Anxiety

Meditation trains you to center your mind while relaxing your body. With regular practice, you can learn better ways of managing stress or coping with anxiety.

Patients who engage in their exercises during physical therapy sessions have low stress levels. This means that with less stress, they can concentrate well on their movements. This can help them gain maximum advantages from any given treatment process.

- Enhanced Pain Management

Meditation teaches individuals how to be present, focus on the mind, and relax their bodies.

They can do this and calm down over-stimulated nerves when experiencing pain. Practicing meditation regularly will enable you not only to cope with pain but also make it feel less severe.

- Enhanced Focus and Concentration

Meditation helps individuals to get more control of their minds and concentrate on what they are doing now.

As a result, these distractions will not tamper with an individual’s performance level. In physiotherapy, focus is vital when performing exercises. Patients gain maximum advantage from their therapy because it enables them to carry out movements correctly.

- Promotion of Mind-Body Connection

Your body can react due to how you feel mentally, affecting your physical body since the two are linked. Meditation helps people establish that bond between their minds and bodies by allowing them to be more in touch with themselves.

Meditation is about helping individuals understand why their bodies may feel this way. This is because it focuses on knowing more about our bodies’ daily stimuli. This makes an individual more aware of how his/her emotions can affect him/her physically.

- Boosting Recovery and Rehabilitation

To heal faster after an injury or illness, you have to think about ways to help meditate, which can help to increase the recovery process. It is a different way of relaxing your mind and body, supporting quick healing. Therefore, meditation can promote relaxation and lower stress levels, facilitating natural healing.

- Improved Mental Health

When your mind is well, it may promote your body’s healing process. Meditation is like a special kind of calming thought and feeling tranquil inside you. Meditation assists people to loosen up and eliminate stress from their brains.

Your sound mental health is connected with how well your body heals itself. A person’s body tends to recover faster from injuries or surgeries when feeling happy and less stressed.

Conclusion

Through meditation in his sessions, a therapist may increase the concentration ability of an individual patient. This helps increase mind-body connection and improves either self-confidence or self-esteem. It also helps accelerate recovery and improve the quality and quantity of sleep duration. Contact us now for professional physiotherapy advice on integrating meditation techniques into the physiotherapy program.

Conscious Living: Understanding the Environmental Impact of Garage Door Choices

In our quest for a more sustainable and eco-friendly lifestyle, it’s crucial to examine every aspect of our living spaces, including the often-overlooked garage doors. These seemingly mundane elements play a significant role in our environmental footprint. As conscientious citizens of Canada, understanding the impact of […]

Home ImprovementIn our quest for a more sustainable and eco-friendly lifestyle, it’s crucial to examine every aspect of our living spaces, including the often-overlooked garage doors. These seemingly mundane elements play a significant role in our environmental footprint. As conscientious citizens of Canada, understanding the impact of our choices is essential. This article delves into the environmental considerations associated with garage door choices, shedding light on the importance of conscious decision-making.

The Environmental Footprint of Garage Doors:

1. Material Matters:

Garage doors come in various materials, each with its own environmental implications.

– Wood: Often favoured for its aesthetic appeal, wood garage doors contribute to deforestation.

– Steel: While durable, the production of steel involves significant energy consumption and emissions.

– Aluminum: Lightweight and corrosion-resistant, aluminum is energy-intensive to extract and process.

2. Energy Efficiency:

The energy efficiency of garage doors impacts both the environment and household expenses.

– Insulation: Opting for insulated doors helps regulate temperature, reducing the need for heating or cooling.

– Weather Stripping: Proper sealing prevents drafts, further enhancing energy efficiency.

3. Manufacturing Processes:

The methods used by custom garage door manufacturers greatly influence their environmental impact.

– Local Production: Choosing locally manufactured doors reduces transportation-related emissions.

– Sustainable Practices: Manufacturers employing eco-friendly processes and materials contribute to a greener industry.

The Impact on Canada’s Ecosystem:

Canada, with its diverse ecosystems and commitment to environmental conservation, requires a thoughtful approach to sustainable living. Here’s how garage door choices can affect the Canadian landscape:

1. Climate Considerations:

– In colder regions like Alberta and Quebec, insulated garage doors become crucial for energy conservation.

– Coastal areas like British Columbia may benefit from corrosion-resistant materials due to the moist climate.

2. Wildlife and Biodiversity:

– Habitat destruction linked to certain garage door materials can impact local wildlife.

– Eco-friendly manufacturing practices contribute to the preservation of Canada’s rich biodiversity.

3. Resource Management:

– Choosing materials with minimal environmental impact aligns with Canada’s commitment to responsible resource management.

Making Informed Choices:

1. Research and Awareness:

Before making a decision, consumers should research the environmental aspects of different garage door materials.

2. Local Regulations:

Understanding and adhering to local environmental regulations ensures that choices align with community sustainability goals.

3. Lifecycle Considerations:

Assessing the entire lifecycle of garage doors, from production to disposal, provides a holistic view of their environmental impact.

Conclusion:

In conclusion, the environmental impact of garage door choices is a crucial aspect of conscious living in Canada. By considering the materials, energy efficiency, manufacturing processes, and local implications, we can make choices that align with our commitment to sustainability.

As consumers, our choices matter. Opting for garage doors from responsible and eco-conscious custom garage door manufacturers ensures that we contribute positively to the environment. Let’s take a step towards a greener future by making informed decisions. Explore the range of eco-friendly garage door options available and play your part in building a sustainable Canada.

Remember, every small decision adds up, and together we can create a more environmentally conscious and responsible living space.

8 Ways to boost the benefits of physiotherapy

Physiotherapy plays an important role in our body. It helps people overcome injuries. It manages chronic health conditions, too. Physiotherapy improves overall physical function. While receiving this treatment, there are ways to boost the benefits. Following certain steps can maximize the benefits of physiotherapy. 1. […]

healthPhysiotherapy plays an important role in our body. It helps people overcome injuries. It manages chronic health conditions, too. Physiotherapy improves overall physical function. While receiving this treatment, there are ways to boost the benefits. Following certain steps can maximize the benefits of physiotherapy.

1. Talk Openly with Your Physiotherapist

You should tell them about your personalized physiotherapy programs. Discuss any discomfort or concerns you have. This open communication is vital. It ensures the treatment plan is tailored for you. The plan will address your specific needs and goals.

2. Follow the Exercise Program Strictly

Doing exercises exactly as prescribed is very important. Being consistent with the program is key. Not following it can prevent full recovery. It may lead to setbacks in your progress.

3. Stay Active Daily

Therapy sessions are very helpful. But, they are not enough. Staying active daily also aids recovery progress. Simple activities like walking or swimming can help. You could do light exercises recommended by your physiotherapist. Any extra physical activity boosts the benefits.

4. Mind Your Posture and Body Mechanics

Proper posture is emphasized in physiotherapy. Using good body mechanics helps too. This reduces strain on your muscles and joints. Poor form can worsen issues or prevent healing. Good posture prevents further injury as well.

5. Manage Stress and Get Enough Rest

Increased stress and lack of rest hinder healing. Too much stress creates tension in the body. Not resting makes it harder to recover.

6. Eat a Balanced, Nutritious Diet

You should eat foods with lean protein. Good options are fish and eggs. Eat plenty of fruits and vegetables too. Also add nuts and healthy fats. Include whole grains in your diet. Eating this way provides energy for tissue repair. The right nutrition fuels the healing.

7. Stay Well Hydrated

Hydration is absolutely vital for recovery. Water consumption is beneficial in numerous ways. Toxins are eliminated from your body via water. It carries vital nutrients to the cells.

Water lubricates the joints as well. All this supports healing and physiotherapy progress.

8. Keep a Positive Mindset

Your mindset impacts healing significantly. Having a good, positive attitude helps a lot. You should celebrate small wins along the way. Remain motivated throughout the treatment process. Mental resilience aids recovery progress tremendously.

To summarize the key points:

- Open communication with your physiotherapist is crucial

- You must follow the exercise program strictly

- Staying physically active daily aids in recovery

- Maintaining proper posture is important

- Managing stress and getting enough rest is vital

- Eating a balanced, nutritious diet provides fuel

- Staying well hydrated supports healing

- Keeping a positive mindset makes a big difference

Conclusion

Follow these eight tips. They can maximize the benefits of physiotherapy. You will heal faster and more completely. Your recovery will be aided tremendously. Using these strategies helps you reach peak health. Engage fully in the process for the best results. Collaborate closely with your physiotherapist as well. Doing so unlocks the full potential of your treatment. Our team at Active Physio Wellness Centre has extensive training in individualized physical therapy. Make an appointment right now to start along the path to a better, more functional version of yourself.

5 most typical garage door color options

The correct color for your garage door dramatically differs from your home’s look. Here are the five colors people like the most for garage doors or industrial sectional overhead doors. We’ll keep it simple and straightforward to help you choose the best color for your […]

Home ImprovementThe correct color for your garage door dramatically differs from your home’s look. Here are the five colors people like the most for garage doors or industrial sectional overhead doors. We’ll keep it simple and straightforward to help you choose the best color for your home’s outside.

White

Lots of people go for white when it comes to garage doors. It’s popular because it looks clean and brings a positive vibe. If your house has white trim, having a white garage door fits in nicely. White garage doors also reflect light, making them suitable for different homes. This light-reflecting quality adds to how nice it looks and brightens your garage area with natural light. So, white garage doors are versatile and work well for many different home styles, giving your place a bright and welcoming feel.

Neutral Colors (Beige, Tan)

Many homeowners like neutral colors like beige and tan. These colors work well with many colors you might have outside your house. Beige or tan is a safe bet, giving your garage door a classic and timeless look. Whether your home looks more traditional or modern, these neutral tones fit in smoothly, adding a simple yet elegant touch. Beige and tan colors can stand the test of time, staying stylish for a long while. That’s why they are good choices for people who want a garage door color that stays cool over the years.

Gray

Soft grey is a stylish and classy pick for garage doors. Many people like it because it looks chic. Warm grey goes well with almost any color and gives a welcoming vibe. It’s especially great for houses with wood siding on the outside. The warm grey with wood becomes a cosy, inviting appearance for the garage door. It works to make your home look even better for people looking.

Black

Black is a classic color for garage doors. This has a very timeless and classy feel. While black absorbs very little light and looks dark, it is still used. When discussing black, it is essential to understand the amount of natural light around your garage. With enough light, the black can provide your home’s exterior with a little hint of elegance.

Wood-Look Finishes

Stained wood-look steel doors are an excellent option for those who love the natural look of wood but want something other than the upkeep. These doors feature wood tones ranging from medium oak to walnut. A wood-look finish can create a cosy and welcoming vibe outside your home. It is a very convenient option for those who love the beauty of the wood without dealing with the many inconveniences associated with maintaining it. Contact one of the popular garage door builders in Canada to inquire about their maintenance contract.

Conclusion

These garage door color options provide a wide range of choices that can fit into various house types and personal tastes. Whether you prefer the sophistication of the grey, the classic beauty of the black, or even wood-look styles for a touch of warmth, each choice has its charm. Through such color palettes, homeowners can increase the curb appeal of their houses with a lasting and very positive impact.

by Liam Snow

7 Ways Exercise can boost brain function

When we talk about getting healthier, we often forget how exercise can also make our brains work better. Here are seven ways exercise helps our brain to be sharper and work well according to online top-notch fitness programs. 1. Memory and Learning Exercise is more […]

FitnessWhen we talk about getting healthier, we often forget how exercise can also make our brains work better. Here are seven ways exercise helps our brain to be sharper and work well according to online top-notch fitness programs.

1. Memory and Learning

Exercise is more than just sweating; it helps our memory and learning. When we exercise, our brain releases growth factors. These growth factors help to make our brain cells healthier. They also help in creating new blood vessels. Studies show that regular aerobic exercise makes the hippocampus more better. This is the part that helps in learning and memory.

2. Reduction of Anxiety and Depression

It makes the body comfortable and our brain alert. It reduces your stress and the likelihood of being depressed. Exercise also makes us sleep better and is suitable for our mental health. It helps us handle stress and worry, which are big reasons our thinking can get fuzzy.

3. Fights against Cognitive Decline and Dementia

As we get older, we can about our thinking getting worse, leading to dementia. Doing regular exercise can help prevent this. Research shows that people who don’t move much are almost twice as likely to have their thinking decline. This means that moving our bodies can lower the chances of our thinking worsening as we age.

4. Neurogenesis

Exercise does something unique for our brains by helping create new brain cells. This process is what is called neurogenesis. Making new brain cells is crucial for improving our thinking—helping us learn, think, and remember things more easily. This is why exercising at any chance you get is essential. This will help you in the long term.

5. Expression of Genes and Neurotransmitters

Exercise helps boost the activity of specific genes that help protect our brains. These genes meet the need for antioxidants to stimulate our brains. Exercise also affects dopamine, noradrenaline, and serotonin – neurotransmitters. These have significant roles in how our brains function.

6. Protection Against Aging Fast

Getting older can make our brains less sharp, and exercise can help. It protects our brains from getting old and some diseases. Exercise also connects our brain cells healthily. This is a way of assisting them to talk to each other better.

7. Vascularization and Antioxidation

Exercise assists blood vessels that are compatible with the brain. It also functions as an antioxidant that preserves the integrity of our neurons. Plus, exercise helps control particular factors that help our brain cells grow and stay healthy. When you combine most of these things, it makes our brains work better overall.

Conclusion

Exercise is a powerful tool that keeps our brains in shape. It works by making new brain cells to protect against aging. The benefits of exercise on our cognitive function are something you can see. It is essential that you exercise daily. Consistency will help you build this resilience that can also help you get the brain benefits. Keep doing the exercises for a healthier body and a sharper mind. Get assistance for more tips and guidance on staying healthy.

Shoplifting in Canada: Understanding Criminal Charges

Shoplifting is a prevalent issue in Canada, and it’s essential to understand the criminal charges and legal consequences that come with this offence. This article aims to provide an informative and educational guide for our Canadian readers, shedding light on the seriousness of shoplifting, its […]

Law & LegalShoplifting is a prevalent issue in Canada, and it’s essential to understand the criminal charges and legal consequences that come with this offence.

This article aims to provide an informative and educational guide for our Canadian readers, shedding light on the seriousness of shoplifting, its legal ramifications, and the importance of seeking professional help when facing such charges.

I. What is Shoplifting?

Shoplifting, also known as theft under the Criminal Code of Canada, refers to the act of taking or attempting to take something from a retail store without paying for it. Shoplifting can take various forms, including:

- Concealing merchandise on one’s person or in bags.

- Swapping price tags to pay a lower price.

- Intentionally damaging goods with the intent not to purchase them.

- Collaborating with an employee to commit theft.

II. Legal Consequences of Shoplifting in Canada

Shoplifting is not a minor offence in Canada. The legal consequences can be severe, depending on the value of the stolen goods and other circumstances.

Here are the primary legal consequences of shoplifting:

- Criminal Charges: Shoplifting is considered a criminal offence in Canada, and those caught may face charges under the Criminal Code. These charges can have a lasting impact on one’s criminal record.

- Penalties: Penalties for shoplifting can include fines, probation, community service, or even imprisonment. The severity of penalties depends on the value of the stolen goods, prior convictions, and the circumstances of the offence.

- Criminal Record: A shoplifting conviction can result in a permanent criminal record, which can have significant consequences on future employment, travel opportunities, and personal reputation.

- Civil Liability: In addition to criminal charges, shoplifters can be held civilly liable for damages, meaning they may have to pay restitution to the retailer for the stolen goods and any related losses.

- Employment Implications: Having a shoplifting conviction on your record may limit future job opportunities, as many employers conduct background checks. It’s crucial to seek legal counsel to understand your rights and options.

III. Why You Need Professional Legal Help

Facing shoplifting charges can be daunting, and that’s where affordable criminal lawyers in Brampton can make a significant difference.

Here’s why you should consider seeking professional legal assistance:

- Legal Expertise: Criminal lawyers in Brampton have the knowledge and experience to navigate the legal system effectively, ensuring that your rights are protected and advocating for the best possible outcome.

- Reducing Charges: A skilled attorney can work to reduce or dismiss your charges, minimizing the impact on your criminal record.

- Sentence Mitigation: If you are convicted, a lawyer can help negotiate for reduced penalties, such as fines or community service, instead of imprisonment.

- Guidance and Support: Legal professionals can provide guidance and support throughout the legal process, ensuring that you make informed decisions about your case.

Conclusion

Shoplifting in Canada is a serious offence with significant legal consequences, potentially affecting your future in profound ways. To protect your rights and ensure the best possible outcome, it’s crucial to seek the assistance of professional criminal lawyers in Brampton.

If you’re facing shoplifting charges or want to learn more about your legal options, don’t hesitate to reach out to our experienced team of lawyers. We are here to provide the support and expertise you need during this challenging time.

Remember, when it comes to shoplifting charges in Canada, the right legal representation can make all the difference in securing a more favourable outcome for your case. Don’t face this legal battle alone; take action now to protect your future.

Avoid Making During Your Home Renovation

Undertaking a home renovation is exciting but can also be fraught with challenges. To help ensure your project’s success, here are seven common mistakes to steer clear of: 1. Setting an Unrealistic Budget It is a common pitfall to underestimate the cost of a home […]

Home ImprovementUndertaking a home renovation is exciting but can also be fraught with challenges. To help ensure your project’s success, here are seven common mistakes to steer clear of:

1. Setting an Unrealistic Budget

It is a common pitfall to underestimate the cost of a home renovation. To avoid this mistake, ensure your budget includes a contingency fund of about 20%. The buffer is for unexpected renovation expenses. This includes structural problems, surprise repairs, or design changes. If you prepare for unforeseen events, you’ll be ready for any unexpected financial surprises.

2. Not Complementing the Original Architectural Style:

When you add on or update your home, keeping the original style and adding new elements is important. Your addition should harmoniously complement the existing style. If you use this method, your home will look the same and be worth more when you sell it. Combining old and new elements makes a beautiful and seamless living space.

3. Sacrificing Function for Form

A beautiful renovation is desirable, but it should also serve practical purposes. Before finalizing your design, consider how you’ll use the space daily. When you design your home, consider where you want doors, windows, outlets, and foot traffic. If you focus on form and function, your renovated space will improve your life and meet your needs.

4. Being Too Trendy

While trendy designs can be tempting, they often have a limited shelf life. It’s essential to balance incorporating fresh, modern elements and maintaining timeless design principles. To keep your renovation looking good for a long time, focus on design choices that will stay in style. This method helps you get the most out of your investment and keeps your home looking good for a long time.

5. Rushing the Job

Impatience during a renovation project can lead to costly mistakes and subpar results. Resist the urge to rush through the process. Instead, allocate sufficient time for thorough planning, proper execution, and necessary inspections. By renovating at a steady pace, we can ensure that each phase is done well.

6. Neglecting the Budget

It’s important to make a budget and stick to it while working on the project. To stay within your budget, don’t buy things you don’t need or make sudden decisions that cause you to spend too much. Manage your budget well, track expenses, prioritize spending, and make informed choices. Taking care of your budget helps you stay financially secure and maximize your money.

7. Neglecting the Team Dynamic

A successful home renovation often involves collaborating with home remodeling experts, contractors, designers, and tradespeople. Ensure that everyone involved understands your vision, project goals, and timelines. To keep your renovation on track, stay updated, and have clear expectations. This helps maintain a cohesive team and allows for better understanding.

Conclusion

You can confidently begin renovating your home by following these tips and avoiding mistakes. To have a successful renovation, start by planning carefully. Create a realistic budget and balance form and function. Prioritize timeless design principles. This will ensure your vision and your home’s future are well-invested in.

When should you see a dentist for your wisdom teeth?

Sometimes, people may have problems dealing with their wisdom teeth. According to family dentistry, many people don’t know how to care for wisdom teeth. Here are simple signs indicating it’s time to see a dentist for your wisdom teeth. Pain and Discomfort Some discomfort or […]

healthSometimes, people may have problems dealing with their wisdom teeth. According to family dentistry, many people don’t know how to care for wisdom teeth. Here are simple signs indicating it’s time to see a dentist for your wisdom teeth.

Pain and Discomfort

- Pain and Discomfort

Some discomfort or pain in your back teeth can signify some issues with your wisdom teeth. Many people usually have this issue, making one reason why you should consult a dentist. They can check it out and tell you what to do. Wisdom teeth problems often show up as pain. It’s essential to take care of it early to avoid more issues.

- Difficulty in Opening Mouth

Difficulty in opening your mouth or experiencing pain could indicate issues with your wisdom teeth. This might happen because the teeth are growing funnily or causing swelling. Seeing a family dentist can help you to know how to fix it and how to take care of it. A dentist can discover why your mouth is having an issue to open and help you with the proper treatment.

- Gum Inflammation and Swelling

Ignoring gum problems can lead to more significant mouth issues, so getting help early is good. Your family dentist can look closely and suggest treatments. Taking care of gum issues early on can stop more substantial difficulties and keep your mouth healthy.

- Jaw Stiffness

Feeling stiff or in pain around your jaw, especially near your wisdom teeth, might indicate a problem. A family dentist can check if your wisdom teeth are causing the trouble. Finding out early can prevent the problem from worsening and affecting your jaw.

Getting professional advice for jaw stiffness means finding out what’s wrong and getting help to feel better.

- Difficulty in Cleaning

Because wisdom teeth are in a tricky spot, cleaning them well can be challenging. This raises the chances of getting cavities and gum problems. Talking to your family dentist is a good idea if you struggle to clean your wisdom teeth. They can teach you the best way to clean them and suggest things to help.

Your dentist can show you how to clean your wisdom teeth, stopping future dental problems.

- Tooth Crowding

Wisdom teeth showing up can sometimes crowd your other teeth or move around. If you notice changes in how your teeth fit together, talking to a family dentist is smart. They can check if your wisdom teeth are the reason and suggest things to fix the problem. Getting help early can stop issues with your teeth fitting together and keep them in the right place.

Family dentistry likes to prevent problems, so dentists can monitor how your wisdom teeth grow. Regular check-ups mean finding issues early and getting help if needed.

Conclusion

Whether your teeth hurt or you want to be careful, family dentistry has the answers for dealing with wisdom teeth issues. Schedule regular check-ups, pay attention to how your mouth feels, and talk to your dentist for personalized advice on caring for your wisdom teeth.

by Liam Snow

Decoding Leach Fields: Usage, Maintenance, and Optimization

Leach fields, also known as drain fields, are a critical component of septic systems, playing a crucial role in the disposal and filtration of wastewater. Understanding how leach fields function, their proper usage, and the importance of maintenance is vital for homeowners relying on septic […]

Beauty & FashionLeach fields, also known as drain fields, are a critical component of septic systems, playing a crucial role in the disposal and filtration of wastewater. Understanding how leach fields function, their proper usage, and the importance of maintenance is vital for homeowners relying on septic systems. This article aims to Decoding Leach Fields, offering valuable insights into their usage, maintenance, and optimization for the audience in Canada.

Understanding Leach Fields

1. Purpose and Functionality

- Wastewater Filtration: Leach fields are designed to filter and distribute treated wastewater into the soil.

- Final Stage: After wastewater undergoes treatment in the septic tank, the clarified effluent is released into the leach field for further purification.

2. Location and Design

- Below Ground: Leach fields are typically located underground, covering a significant area.

- Pipe Network: Perforated pipes distribute the treated wastewater evenly across the leach field.

- Soil Interaction: The soil in the leach field absorbs and treats the effluent, providing a natural filtration process.

Proper Usage of Leach Fields

1. Waste Disposal Practices

- Septic-Friendly Products: Use septic-safe household products to avoid harmful chemicals that can disrupt the microbial balance in the septic tank and leach field.

- No Hazardous Waste: Refrain from disposing of hazardous materials in sinks or toilets as they can harm the septic system.

2. Water Conservation

- Moderate Water Usage: Excessive water usage can overload the septic system, affecting the efficiency of the leach field.

- Spread Out Water Usage: Avoid large amounts of water usage in a short period, such as consecutive loads of laundry, to prevent system overload.

Maintenance Practices for Leach Fields

1. Regular Inspections

- Professional Inspections: Schedule regular inspections by septic tank services to assess the overall health of the septic system.

- Visual Checks: Homeowners can observe the leach field area for any signs of pooling water or foul odours.

2. Pumping the Septic Tank

- Scheduled Pumping: Regular septic tank pumping prevents the accumulation of solids that may harm the leach field.

- Professional Services: Hire experienced septic tank services to perform proper pumping and maintenance.

3. Avoiding Heavy Loads

- Limit Heavy Equipment: Avoid driving heavy vehicles or equipment over the leach field, as it can compact the soil and hinder proper water absorption.

- Landscaping Caution: Exercise caution when landscaping around the leach field to prevent damage to pipes and soil.

Optimizing Leach Field Performance

1. Soil Aeration

- Aeration Practices: Implement soil aeration techniques to enhance the absorption capacity of the leach field.

- Professional Consultation: Seek advice from septic tank services on appropriate aeration methods.

2. Planting Grass

- Grass Cover: Planting grass over the leach field helps prevent soil erosion and encourages natural filtration.

- Avoid Trees and Shrubs: Refrain from planting deep-rooted trees or shrubs that may interfere with the leach field infrastructure.

Conclusion

Decoding leach fields is crucial for Care for Your Septic System. Proper usage, regular maintenance, and optimization practices contribute to the longevity and effectiveness of leach fields. Homeowners should stay informed about best practices to ensure the reliable performance of their septic systems.

For homeowners in Canada looking to ensure the optimal performance of their septic systems and leach fields, it is essential to engage with experienced septic tank services. These professionals can provide expert advice, conduct regular inspections, and offer maintenance services to keep the septic system in top condition.

Take the proactive step toward a well-maintained septic system; connect with reputable septic tank services for reliable support and guidance.

How Audio-Visual Solutions Impact Retail Environments

In today’s rapidly evolving retail landscape, creating a memorable and engaging shopping experience has become more crucial than ever. As consumer expectations continue to grow, retailers are seeking innovative ways to capture their attention and foster a strong connection. One such impactful approach is the […]

BusinessIn today’s rapidly evolving retail landscape, creating a memorable and engaging shopping experience has become more crucial than ever. As consumer expectations continue to grow, retailers are seeking innovative ways to capture their attention and foster a strong connection. One such impactful approach is the integration of audio-visual solutions within retail environments. By harnessing the potential of audio-visual technology, retailers can transform their spaces into immersive and dynamic settings that leave a lasting impression on customers.

This article delves into the significance of audio-visual solutions in enhancing the retail experience and explores how they influence customer engagement, brand perception, and overall sales.

Enhancing Engagement Through Immersion

In a world inundated with visual stimuli, creating an immersive environment is paramount for capturing customers’ attention. Audio-visual solutions offer a multifaceted approach to engagement, leveraging both sight and sound to draw customers into the retail experience. By integrating large, high-definition displays and strategically placed speakers, retailers can create captivating visual and auditory displays that tell a compelling brand story.

- Visual Storytelling: Immersive visuals provide an opportunity to convey a brand’s ethos and message seamlessly. High-quality displays can showcase product features, benefits, and real-world applications, allowing customers to envision the role of the product in their lives.

- Sensory Appeal: The synergy of audio and visual elements stimulates multiple senses simultaneously, creating a more profound and memorable experience. Studies have shown that multisensory engagement leads to increased emotional attachment to brands and products.

- Interactive Touchpoints: Touchscreen displays and interactive kiosks enable customers to explore products and information in a hands-on manner. This interactive engagement fosters a sense of involvement and empowerment, helping customers make more informed purchasing decisions.

Influencing Brand Perception

A well-executed audio-visual strategy not only engages customers but also shapes their perception of a brand. By orchestrating a harmonious blend of aesthetics, sound, and messaging, retailers can establish a distinct brand identity that resonates with their target audience.

- Elevating Aesthetics: Strategic placement of displays and lighting can enhance the ambiance of retail space. The atmosphere created through audio-visual solutions influences how customers perceive the brand’s sophistication, modernity, and attention to detail.

- Consistency and Coherence: A consistent audio-visual experience across different touchpoints reinforces the brand’s identity and messaging. Whether it’s an in-store display, online video content, or social media campaign, maintaining a unified presentation reinforces the brand’s credibility and reliability.

- Personalization: Advanced audio-visual solutions can be tailored to individual customer preferences. For instance, digital signage can display personalized recommendations based on a customer’s past purchases or browsing history, demonstrating the brand’s understanding and care for its customers.

Boosting Sales and Loyalty

The integration of audio-visual solutions has a direct impact on a retailer’s bottom line. Engaged and emotionally connected customers are more likely to make purchases and become loyal brand advocates.

- Upselling Opportunities: Immersive displays can showcase complementary products and upsell opportunities in an unobtrusive manner. By suggesting products that align with the customer’s current choices, retailers can increase the average transaction value.

- Dwell Time Extension: Engaging audio-visual content can extend customers’ time in-store, providing more opportunities for them to discover products and make purchases.

- Shareable Experiences: Memorable retail experiences are often shared through word-of-mouth and on social media. When customers are delighted by innovative audio-visual displays, they are more likely to share their experiences, effectively becoming brand ambassadors.

Conclusion

The integration of audio-visual solutions in retail environments represents a transformative shift in how brands engage with their customers. By leveraging immersive visuals and sound, retailers can create memorable experiences that resonate with customers on an emotional level.

Incorporating audio-visual solutions into your retail space has the potential to elevate your brand’s impact and customer engagement. To explore how audio-visual solutions can be tailored to your unique brand identity and customer preferences, contact us for a consultation. Let us help you transform your retail environment into an immersive, dynamic, and unforgettable shopping experience that keeps customers coming back for more.

Remember, the world of retail is changing, and embracing audio-visual solutions could be the key to staying ahead in this dynamic landscape.

by Liam Snow

What kind of injuries are typically claimed in injury suits?

When someone hurts you, you can ask for money to help with your injuries. This request is called an injury suit. Long-term disability lawyers in Brampton often handle these suits. They cover various incidents causing harm. People file these claims to cover injury costs. This […]

healthWhen someone hurts you, you can ask for money to help with your injuries. This request is called an injury suit. Long-term disability lawyers in Brampton often handle these suits. They cover various incidents causing harm. People file these claims to cover injury costs. This is where individuals seek compensation for the damage they’ve suffered. Let’s explore the common types of injuries that lead to these suits in simple Canadian English.

Car Accidents

Car accidents are a common reason for these cases. People can get hurt in crashes, leading to hefty medical bills. Lawyers who focus on injury cases guide individuals through the legal process. They help them obtain the necessary money for recovery.

Slip and Fall Accidents:

People might get hurt if they slip and fall because the place is not safe. In such cases, the injured person may seek compensation. They can request money for injuries and lost wages if they can’t work. Specialized injury lawyers assist and guide them through this claim process.

Medical Malpractice

Doctors or nurses making mistakes can lead to harm. This harm may result in an injury case. Patients might ask for money to cover medical costs and for the pain they went through. Disability lawyers are experts at handling these situations. They work on helping patients step by step to get the right amount of money.

Work-Related Injuries

People might file a case for work-related injuries. If someone gets hurt at work, they can claim money for medical bills and lost wages. Specialized injury lawyers help them build a strong case.

Product Defects

If something a person bought is dangerous and causes harm, they might file a case against the company that made it. This is called a product defect case. Disability lawyers play a significant role in ensuring these companies are responsible and helping the person who got hurt.

Assault

The injured person might file a case when someone intentionally hurts another person. They could ask for money to help with their medical bills and the pain they went through. Lawyers specializing in injury cases guide them through the legal process.

Dog Bites

If a dog hurts someone, the injured person might file a case. They could claim money for their medical bills and lost wages because they couldn’t work. Lawyers specializing in injury cases assist in these cases. They work on helping victims get the proper compensation for their injuries and losses.

Conclusion

Injury suits cover different situations where people get hurt. Lawyers who specialize in injury cases help with other conditions. They assist in cases like car accidents and slips and falls. These lawyers are also experts in dealing with injuries caused by doctors’ mistakes and work-related incidents. You can also contact them if you suffer from the effects of defective products, assault, and dog bites. In Brampton, long-term disability lawyers play a significant role in helping through these challenging situations. They can ensure a smooth legal process and fair compensation.

8 Key Garage Door Maintenance Tips That Can Help Prevent Costly Future Repairs

Every homeowner understands the importance of maintaining their home, but the garage door is often overlooked. However, this essential part of our homes provides safety, security, and convenience. Regular maintenance from garage door experts can help prevent costly future repairs and extend the life of […]

Home ImprovementEvery homeowner understands the importance of maintaining their home, but the garage door is often overlooked. However, this essential part of our homes provides safety, security, and convenience. Regular maintenance from garage door experts can help prevent costly future repairs and extend the life of your garage door. Here are eight key garage door maintenance tips that every homeowner should know.

Regularly Inspect the Garage Door’s Hardware

Look for loose bolts and brackets holding your garage door and tracks together. Over time, these can loosen due to the door’s movements. Tighten them with a socket wrench to ensure they are secure and your door functions well.

Lubricate the Moving Parts

Your garage door has several moving parts that need regular lubrication. Applying a high-quality lubricant to hinges, rollers, and springs will keep them working smoothly and prevent wear and tear. Just a few minutes spent on this task can save you from expensive repairs in the future.

Check the Garage Door Balance

An unbalanced garage door will have to work harder, which can lead to a shorter lifespan. Disconnect the opener and manually lift the door halfway up to check the balance. If it doesn’t stay in place, it means the springs might need adjustment by a professional.

Ensure the Garage Door Opener Works Properly

Your garage door opener plays a key role in operating your door. Check for signs of trouble, such as slow movement, strange noises, or incomplete opening. If you notice any of these, consult a garage door repair service to avoid potential issues.

Clean the Garage Door Regularly

Regular cleaning can prevent rust and corrosion. Use a mild detergent and a soft sponge or cloth to clean the door. Don’t forget to rinse thoroughly. Repainting your door can add an extra layer of protection and keep it looking fresh.

Check the Door’s Weatherstripping

The weatherstripping at the bottom of your garage door helps keep out rain, snow, and cold air. Regularly inspect it for wear and replace if needed. It not only protects your garage contents but also increases energy efficiency.

Inspect and Replace the Rollers

Whether your door has steel or nylon rollers, you should inspect them twice a year. Look for signs of wear, chips, or cracks. If they are damaged, consider replacing them to ensure your door operates smoothly.

Test the Garage Door’s Safety Features

Most garage doors have safety features like auto-reverse and motion sensor functions. Test these regularly to ensure they work correctly. A non-functioning safety feature can be dangerous and lead to accidents.

Maintain Your Door, Secure Your Home

In conclusion, maintaining your garage door isn’t a daunting task, but it is crucial for the safety and longevity of your door. Regularly following these eight simple steps can help prevent major problems and costly repairs in the future. Remember, always call a professional if you ever feel unsure about a garage door issue. After all, a well-functioning garage door keeps your property secure and ensures peace of mind. Be proactive, maintain your garage door, and enjoy its benefits.

Different Types of Garage Doors for Your Home: A Quick Guide

Garage doors play a crucial role in enhancing the aesthetics and security of your home. Choosing a new garage door can be overwhelming, especially with the various types of garage doors available in the market. In this quick guide, we will explore the different types […]

Home ImprovementGarage doors play a crucial role in enhancing the aesthetics and security of your home. Choosing a new garage door can be overwhelming, especially with the various types of garage doors available in the market.

In this quick guide, we will explore the different types of garage doors to help you make an informed decision.

Types of Garage Doors

There are four main types of garage doors. These include:

- Sectional Garage Doors: These are the most popular garage doors in Canada. They are made of horizontal panels that slide upwards and rest parallel to the ceiling when open. Sectional garage doors are available in various materials, including steel, aluminum, and wood.

- Roller Doors: Roller doors are made of a single curtain of material that rolls up and down around a drum. They are suitable for homes with limited headroom, as they do not require overhead space.

- Side-Hinged Garage Doors: These doors open outwards like traditional doors and are ideal for garages with limited headroom. Side-hinged garage doors are available in various materials, including steel, wood, and aluminum.

- Up and Over Garage Doors: Up and over garage doors swing outwards and then upwards to open. They are available in various materials and are suitable for homes with ample headroom.

Material Options

The material of your garage door is an important consideration when choosing a new garage door. The following are the common materials used to make garage doors:

- Steel: Steel garage doors are durable, low maintenance, and affordable. They are available in various styles, colours, and finishes, making them a popular option for homeowners.

- Wood: Wood garage doors provide a natural and warm look to your home. They are available in various styles and finishes, including cedar, hemlock, and mahogany. However, they require more maintenance than other materials and are more expensive.

- Aluminum: Aluminum garage doors are lightweight, low maintenance, and durable. They are available in various styles and finishes, including wood grain finishes. However, they are less energy-efficient than other materials.

- Fibreglass: Fiberglass garage doors are lightweight, durable, and low maintenance. They are available in various finishes, including wood grain finishes. However, they are less durable than other materials and can crack or fade over time.

Additional Features

When choosing a new garage door, you may also want to consider the following additional features:

- Insulation: Insulated garage doors can help to improve energy efficiency, reduce noise, and provide additional strength to the door. Insulation is especially important if you use your garage as a living space or have rooms above the garage.

- Windows: Garage doors with windows can help to improve the aesthetics of your home and provide natural light to your garage. However, they may compromise your privacy and security.

- Security: Garage doors with additional security features, such as tamper-resistant locks and alarms, can help to enhance the security of your home.

Conclusion

Choosing a new garage door can be overwhelming, but with this quick guide, you can make an informed decision. Consider the type of garage door, material options, and additional features before making your final decision. A new garage door can enhance the aesthetics and security of your home, so choose wisely.

If you are looking for a professional and reliable garage door installation service in Canada, contact us today. Our team of experts can help you choose the right garage door for your home and provide professional installation services. Choose us for quality service and guaranteed customer satisfaction.

How to Give the Right Flowers as Thank You Gift

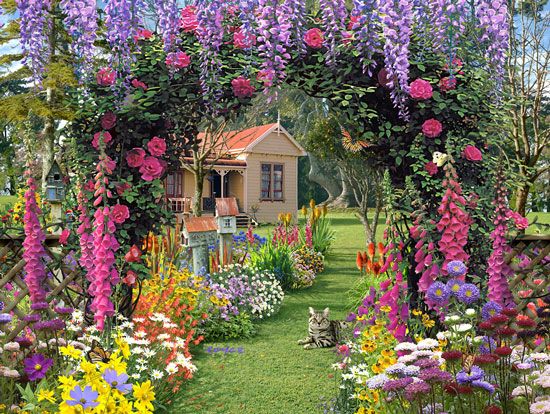

Looking for a unique way to say “thank you” to someone special? Well, have you ever considered the magic of flowers? Flowers can convey heartfelt gratitude like no other gift. You can even send a thoughtful thank-you gift by arranging a birthday flower delivery! But […]

flowersLooking for a unique way to say “thank you” to someone special? Well, have you ever considered the magic of flowers? Flowers can convey heartfelt gratitude like no other gift. You can even send a thoughtful thank-you gift by arranging a birthday flower delivery! But how do you choose the right flowers to express your appreciation? Here are idea to choose the right flowers as thank you gift

Consider the Recipient’s Preferences

When selecting flowers as a thank-you gift, it’s important to consider the person you are giving them to. What colours do they like? Do they have a favourite type of flower? By considering their preferences, you can make your gift even more meaningful. You can always choose classic and universally loved flowers like roses or daisies if you still decide.

Express Emotions with Flower Meanings

Did you know that flowers can have different meanings? Each type of flower can convey a specific emotion or sentiment. For example, roses symbolize love and gratitude, while sunflowers represent happiness and warmth. Learn about flower meanings and language flowers and choose the ones that align with your thank you message. It will make your gift extra special.

Think about the Occasion

Consider the occasion when giving flowers as a thank-you gift. Is it a birthday, a wedding, or a simple gesture of appreciation? The occasion can guide your flower choice. For instance, if it’s a birthday, you can add a festive touch by selecting bright and vibrant flowers. On the other hand, elegant flowers like orchids or lilies might be a better choice for a more formal occasion.

Personalize with a Handwritten Note

Remember to include a heartfelt handwritten note along with the flowers. A simple “thank you” can go a long way in expressing your gratitude. Take a moment to write a few kind words about why you are grateful and how much the person means to you. It will make your gift even more meaningful and show that you put thought and effort into it.

Final Words

Choosing the right flowers as a thank-you gift is a thoughtful gesture that can make someone feel appreciated. By considering the recipient’s preferences, flower meanings, and the occasion, you can create a personalised gift that will leave a lasting impression. Remember to accompany your flowers with a handwritten note to express your gratitude in words.

Giving flowers as a thank-you gift is a beautiful way to show appreciation, whether for a friend, a family member, or a teacher. So, next time you want to say “thank you,” consider the power of flowers. They will surely bring a smile to the recipient’s face and warm their heart.

Why not brighten someone’s day today? Take a moment to think of someone who has done something kind for you and deserves a thank-you gift. Choose a beautiful bouquet, write a heartfelt note, and make your day memorable. The act of gratitude brings joy to others and fills our hearts with happiness. So go ahead, and spread some cheer with the perfect thank-you gift of flowers!

by Liam Snow

17 Reasons Why Inbound Marketing Enables Local Businesses To Dominate Their Competitors

Inbound marketing is a great way for local businesses to get more customers, gain trust, and stand out from their competitors. Here are 17 reasons why inbound marketing is beneficial for local companies: 1. Improves visibility Inbound marketing helps your business get noticed by creating […]

BusinessInbound marketing is a great way for local businesses to get more customers, gain trust, and stand out from their competitors. Here are 17 reasons why inbound marketing is beneficial for local companies:

1. Improves visibility

Inbound marketing helps your business get noticed by creating fun and informative content. When you reach more people, it helps more people learn about your brand and makes your company more visible online.

2. Provides valuable information

Content marketing educates prospects about their interests. It helps build trust and keeps customers coming back to your brand.

3. Generates more leads

Inbound attracts visitors who convert into leads through calls-to-action. Improve online visibility through natural search engine optimization in Toronto.

4. Converts lead into customers.

Nurtured leads convert at higher rates. Inbound’s multi-touch process builds relationships with prospects.

5. Retains existing customers

Current customers who engage with your brand through inbound are more likely to stay loyal.

6. Lower cost than outbound

Inbound focuses on organic marketing activities, which cost less than disruptive outbound tactics.

7. Improves SEO rankings

Quality content and inbound links signal search engines to rank your pages higher.

8. Builds authority and trust

Inbound establishes your company as an industry authority. This trust makes customers more likely to buy from you.

9. Creates brand advocates

Satisfied inbound customers happily refer others if you provide a good experience. Referrals are powerful.

10. Adapts to mobile users

Inbound is designed for mobile, the primary way people consume content today. It is key for local reach.

11. Aligned with buyer journey

Inbound guides visitors through awareness, consideration, and decision—how people buy now.

12. Flexibility across channels

Inbound efforts across online and offline platforms boost brand visibility. You may reach more people and boost your online and offline exposure by using many channels.

13. Ongoing process, not one-off

For long-term success, consistent inbound actions that compound results over time are essential.

14. Levels playing field

Inbound gives small businesses the same digital access as large companies to attract customers.

15. Adapts to changing technology

Inbound evolves as new marketing channels emerge. This built-in flexibility keeps you competitive.

16. Measurable results

Inbound efforts across online and offline platforms boost brand visibility. You may reach more people and boost your online and offline exposure by using many channels.

17. Customizable strategies

With numerous inbound tactics, you can develop a unique approach tailored to your business.

Conclusion:

Inbound marketing is a proven way for local businesses like yours to attract more customers without spending too much money. It helps you share important information with the right people at the right time by creating useful content on different platforms.

Choose a few inbound strategies that fit your business and resources. Start with a company blog, SEO optimization, email marketing, and social media engagement. Track your efforts and double down on what works. Commit to inbound marketing and watch your visibility, leads, and sales start to climb. When inbound is done right, it’s a game-changer for dominating local competitors. You got this!

by Randal Spain

Navigating the Landscape of Online Couple Therapy

In today’s fast-paced world, relationships are often put to the test by various challenges that arise. Whether it’s communication issues, conflicts, or the struggle to balance personal and professional lives, many couples find themselves seeking guidance to navigate these obstacles and strengthen their bonds. This […]

healthIn today’s fast-paced world, relationships are often put to the test by various challenges that arise. Whether it’s communication issues, conflicts, or the struggle to balance personal and professional lives, many couples find themselves seeking guidance to navigate these obstacles and strengthen their bonds. This is where online counselling for couples comes into play, offering a convenient and effective way for partners to work on their relationships in the digital age. This article explores the landscape of online couple therapy, its benefits, considerations, and how it can provide a path towards healthier and more fulfilling relationships.

The Rise of Online Counselling for Couples

Traditional face-to-face therapy has long been a cornerstone for relationship help, but with the advent of technology, online counselling for couples has gained significant traction. This approach offers several advantages that make it an attractive option for many Canadians:

- Convenience: The digital nature of online couple therapy eliminates the need for couples to travel to a therapist’s office. This is particularly beneficial for those residing in remote areas or having busy schedules.

- Flexibility: Online sessions can be scheduled to accommodate the couple’s commitments, whether it’s work, childcare, or other responsibilities. This flexibility can contribute to a more relaxed and focused atmosphere during therapy.

- Access to Specialized Professionals: Couples facing unique challenges, such as long-distance relationships, can benefit from accessing therapists with specific expertise in these areas, which might not be locally available.

- Reduced Stigma: For some, seeking therapy might carry a certain stigma. Online counselling allows couples to engage in therapy discreetly from the comfort of their own homes.

Benefits of Online Counselling for Couples

Online couple therapy offers a range of benefits that contribute to its growing popularity among Canadians seeking relationship assistance:

- Enhanced Comfort: Couples often find it easier to open up about sensitive topics in familiar surroundings, which can lead to more productive therapy sessions.

- Communication Improvement: A common challenge in relationships is communication breakdown. Online therapy provides a platform for partners to practice healthy communication techniques with the guidance of a professional.

- Time and Cost-Efficiency: With no need to commute, online therapy saves time and money. This can encourage couples to commit to regular sessions, leading to more sustainable progress.

- Record Keeping: Online sessions can be recorded with consent, allowing couples to revisit discussions and insights between sessions.

- Couples’ Participation: Engaging in therapy from home can encourage equal participation from both partners, fostering a sense of shared responsibility for the relationship’s growth.

Considerations for Online Couple Therapy

While online counselling for couples offers numerous advantages, there are factors to consider to ensure a successful experience:

- Technology and Privacy: Stable internet connection and private space are essential for uninterrupted sessions. Couples should also prioritize platforms that prioritize confidentiality and data security.

- Choosing the Right Therapist: Just like in traditional therapy, finding the right therapist is crucial. Couples should research therapists’ qualifications, reviews, and expertise to ensure compatibility.

- Self-Discipline: Engaging in online therapy demands self-discipline. Couples should commit to attending sessions and completing recommended exercises outside of the sessions.

Conclusion

Navigating the landscape of counselling for couples provides a pathway to healthier, more fulfilling relationships. The convenience, flexibility, and personalized guidance online offers align well with the needs and lifestyles of modern Canadians. As technology continues to reshape our lives, embracing online couple therapy can be a pivotal step toward overcoming relationship challenges.

If you and your partner are seeking to enhance your relationship and overcome hurdles, consider exploring the realm of online counselling for couples. With its numerous benefits and the opportunity to work with experienced professionals, online therapy can provide the support and tools you need to build a stronger, more harmonious bond.

6 Key Drawbacks of Mobile Phone Garage Door Apps

Garage door apps are becoming more popular because of their convenience. With just a few taps, you can open or close your garage door from anywhere. But, like all technologies, they have their downsides too. Here are six key drawbacks of mobile phone garage door […]

Home ImprovementGarage door apps are becoming more popular because of their convenience. With just a few taps, you can open or close your garage door from anywhere. But, like all technologies, they have their downsides too. Here are six key drawbacks of mobile phone garage door apps.

These Apps Depend on Your Phone’s Battery Life

One of the main disadvantages of mobile phone garage door apps is that they depend on your phone’s battery life. If your phone’s battery dies, you could be locked out of your garage. In this situation, you need reliable garage door repair & services.

It could be particularly problematic if you return home late at night or during adverse weather conditions. So, while the app adds convenience, you must be extra cautious about keeping your phone charged, especially when you’re out and about.

Garage Door Apps Need a Reliable Internet Connection

Mobile phone apps rely on a stable internet connection to work. If your home’s Wi-Fi network is down or you’re trying to operate the door remotely but don’t have a good signal, you might be unable to open or close your garage door.

This dependence on internet connectivity can be inconvenient and frustrating. It can be hard in emergencies when you need to access your garage immediately.

There Is a Risk of Phone Loss or Theft

While it’s unlikely, there’s always the risk that you could lose your phone or have it stolen. If this happens, someone else could access your garage door app and, by extension, your home. While there are ways to protect your phone and app, such as using strong passwords and biometric security features, it’s still a risk to consider.

There Is a Possibility of App Malfunctions

Garage door apps can experience bugs or glitches like any software. The app could freeze, crash, or stop working for no clear reason. These technical issues can be frustrating, especially when getting into your garage quickly. Even though developers often fix these issues with updates, there’s still the chance of encountering problems.

Some Apps May Not Be User-Friendly

Not all mobile phone apps are created equal. Some are intuitive and easy to use, while others may be more complex. If the app is difficult to navigate or has a steep learning curve, it could make accessing your garage more complicated rather than easier. You might struggle with the app when you’re in a hurry, which could lead to frustration and stress.

There May Be Compatibility Issues with Garage Door Apps

Finally, there may be compatibility issues between your phone and the garage door app. Some apps may not work well with certain operating systems or phone models. If you upgrade your phone or switch to a different operating system, you might need to find a new app or change your garage door system. It could be costly and inconvenient.

Choose the Right Garage Door Carefully

While such garage doors offer benefits, it’s essential to consider these drawbacks. Evaluate your specific situation, your comfort level with technology, and the reliability of your phone and internet connection. If you feel these drawbacks outweigh the benefits. Sticking with a traditional remote or seeking other garage door-opening solutions might be best. Remember, it’s all about finding a solution that fits your lifestyle and needs. Consider consulting with a garage door professional to explore your options and make the best decision for your home.

The Lastest on Hormone Replacement Therapy Safety

First, what are hormones? Hormones are chemical substances produced in the endocrine glands and released into the bloodstream to control the activity of cells and organs. The two key hormones in the female body are progesterone and estrogen. Imbalance estrogen levels have been linked to […]

healthFirst, what are hormones? Hormones are chemical substances produced in the endocrine glands and released into the bloodstream to control the activity of cells and organs. The two key hormones in the female body are progesterone and estrogen. Imbalance estrogen levels have been linked to many health conditions, including endometriosis, fibroids, infertility, fibrocystic breast, cancer, and premenstrual syndrome (PMS). In this blog we will learn about hormone replacement therapy safety. So, First what are hormones read more here to know

female hormone that induces the growth of tissues

Although estrogen is mainly produced in the ovaries, it is also made in other parts of the body, like the liver, adipose cells, breast tissue, and adrenal glands. Estrogen is the female hormone that induces the growth of tissues, and in doing so, it impacts bone formation, libido, breast tissue, and the lining of the womb and vaginal walls

Estrogen three different forms